The building façade is the first element that captures the viewer’s attention and plays a crucial role in shaping the visual identity of a structure. At the same time, a façade must fulfill various functions, including protection against weather conditions, thermal and acoustic insulation, and aesthetic appeal. The dry façade system, as an advanced and efficient solution, is capable of meeting all these requirements simultaneously. In this article, we will explore the features, advantages, and challenges of implementing dry façade systems and introduce their different types along with corresponding installation methods.

History of Dry Façades

The history of dry façades dates back to the early 20th century, with their initial emergence in Europe. During this period, the rise of urbanization and demand for taller buildings prompted architects and engineers to seek solutions that could accelerate construction and mitigate structural challenges. The dry façade system emerged as a direct response, offering faster installation, reduced dead load on buildings, and enhanced design flexibility.

The widespread adoption and serious application of dry façade systems began in the 1950s in Europe and the United States. This era saw the introduction of new materials like aluminum and steel, which facilitated the mechanical installation of facades. In subsequent decades, as the construction industry expanded and a broader range of materials became available, the dry façade system was refined and became a standard practice in modern building construction.

During the 1980s and 1990s, advancements in installation technologies and the introduction of innovations such as ventilated façade systems elevated dry façades to a key component of sustainable and modern architecture. Today, this system is utilized worldwide due to its extensive structural and environmental benefits, and it continues to evolve through ongoing improvements and innovations.

Dry Façade: Types, Advantages, and Disadvantages

The dry façade, also known as the “Dry Façade system,” is a modern method for designing and installing building façades that has gained significant attention in recent years, particularly in Iran. This multi-layered system is installed without the use of traditional mortar or cementitious materials. Due to its unique characteristics, the dry façade has secured a prominent position in the construction industry.

A dry façade designates cladding systems where constituent components are affixed to the building structure without the reliance on mortar or cementitious materials. Instead, mechanical fasteners, such as screws and rails, are utilized to secure the façade panels, hence the appellation “dry” system. This methodology confers numerous benefits, including accelerated installation, reduction in structural dead load, simplified replacement and maintenance procedures, and expanded design versatility.

Choosing the Optimal Dry Façade Installation Method

The selection of an appropriate dry façade installation method is contingent upon several critical factors:

- Material Type: The inherent nature of the façade material (e.g., brick, stone, ceramic) exerts a significant influence on the most suitable installation technique.

- Material Dimensions and Weight: Larger and heavier materials necessitate more robust fastening systems, such as screw-and-plug assemblies or reinforced anchors.

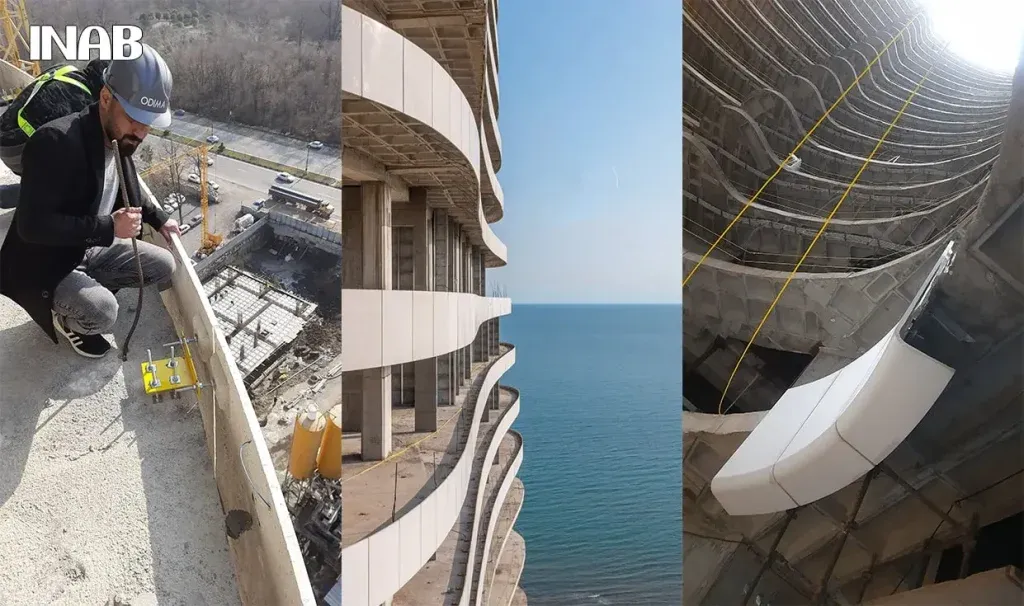

- Façade Design: For intricate or curvilinear façade geometries, rail-and-hook systems or concealed fastening methodologies are generally more appropriate.

- Building Height: In high-rise construction, priority must be given to installation methods that rigorously ensure worker safety, such as specialized scaffolding or lift systems.

- Project Budget: Each installation method carries distinct cost implications, demanding selection in alignment with the project’s financial parameters.

Overall Advantages of Dry Façades

- Expedited Installation: Dry façade systems can be erected substantially faster than conventional façade application methods.

- Reduced Building Mass: They effectively decrease the dead load imposed on the building structure, thereby enhancing seismic resistance.

- Design Versatility: These systems facilitate the realization of diverse and aesthetically compelling architectural designs.

- Thermal and Acoustic Performance: They significantly improve the building’s energy efficiency and sound attenuation capabilities.

- Superior Durability and Longevity: When high-grade materials are employed and installation is executed proficiently, dry façades can exhibit an extended service life.

- Simplified Maintenance: Repair and upkeep of dry façades are inherently less complex compared to traditional façade systems.

Important Note: For the accurate and secure installation of dry façades, it is imperative to engage experienced and proficient contractors and to specify high-quality materials

Introduction to Dry Façade Materials

As a modern cladding methodology, dry façade systems demonstrate compatibility with a diverse array of practical materials. This system employs a metal or aluminum substructure to mechanically attach panels to the building, obviating the need for mortar. This characteristic positions it as an optimal solution for projects with distinct aesthetic and functional prerequisites. The subsequent sections will offer a comprehensive overview of prevalent dry façade materials, detailing their advantages, disadvantages, and associated installation methods.

1. GFRC Dry Façade: Comprehensive Explanation

Glass Fiber Reinforced Concrete (GFRC) is a robust and resilient composite material formulated from cement, water, fine aggregates, and alkali-resistant glass fibers. The precise volumetric proportions of these constituents are meticulously determined based on the specific design and intended application. GFRC panels are manufactured via various techniques, including casting or spraying, and their extensive spectrum of design and color options facilitates the creation of exceptionally intricate and aesthetically compelling facades.

Beyond its superior resistance to impact, thermal fluctuations, and moisture, GFRC also provides excellent thermal and acoustic insulation, coupled with an extended service life. These attributes collectively contribute to augmented structural durability and foster a secure and comfortable internal environment. Furthermore, GFRC’s inherent high fire resistance renders it a safe material choice for high-rise and public edifices.

Installation Methods for GFRC Dry Façades

GFRC (Glass Fiber Reinforced Concrete) represents a contemporary and widely adopted material for building facades. The installation of GFRC facades utilizing dry systems can be accomplished through several distinct techniques. Below is a comprehensive overview of the various installation methods for GFRC dry facades.

1. Metal Framework Systems

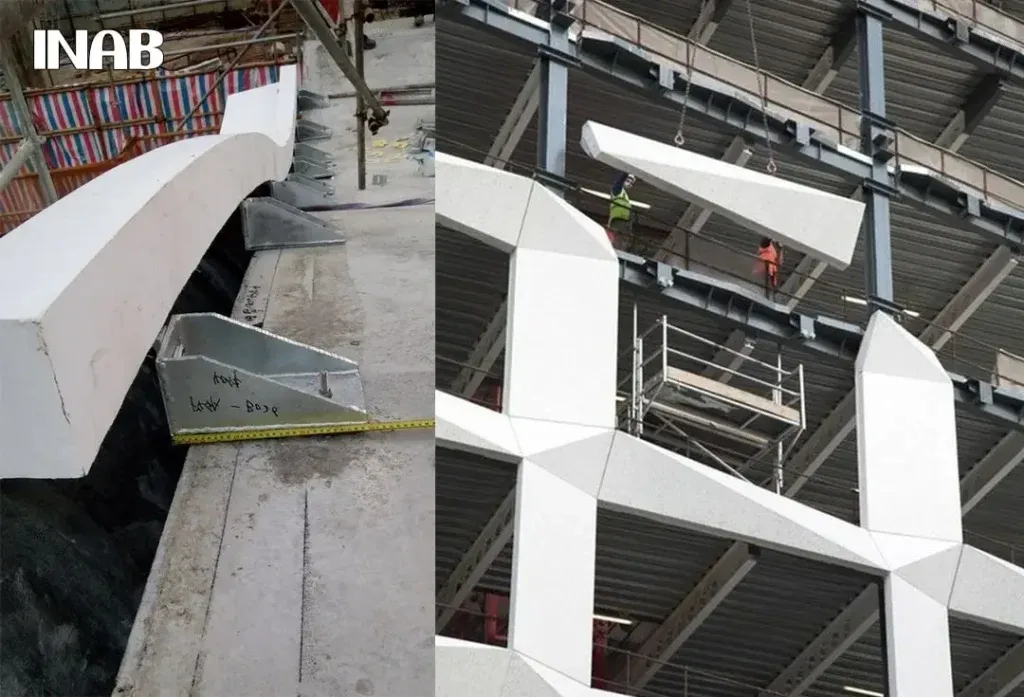

This method involves the attachment of GFRC panels to a robust metal support framework, typically comprising rails, profiles, and various metal connectors. It stands as one of the most prevalent installation techniques for GFRC dry façades.

Components and Installation Steps

- Vertical Profiles: These profiles are directly affixed to the building’s structural wall, functioning as the primary support for subsequent components.

- Horizontal Profiles: Interconnected with the vertical profiles, these establish a precise grid structure that provides direct support for the GFRC panels.

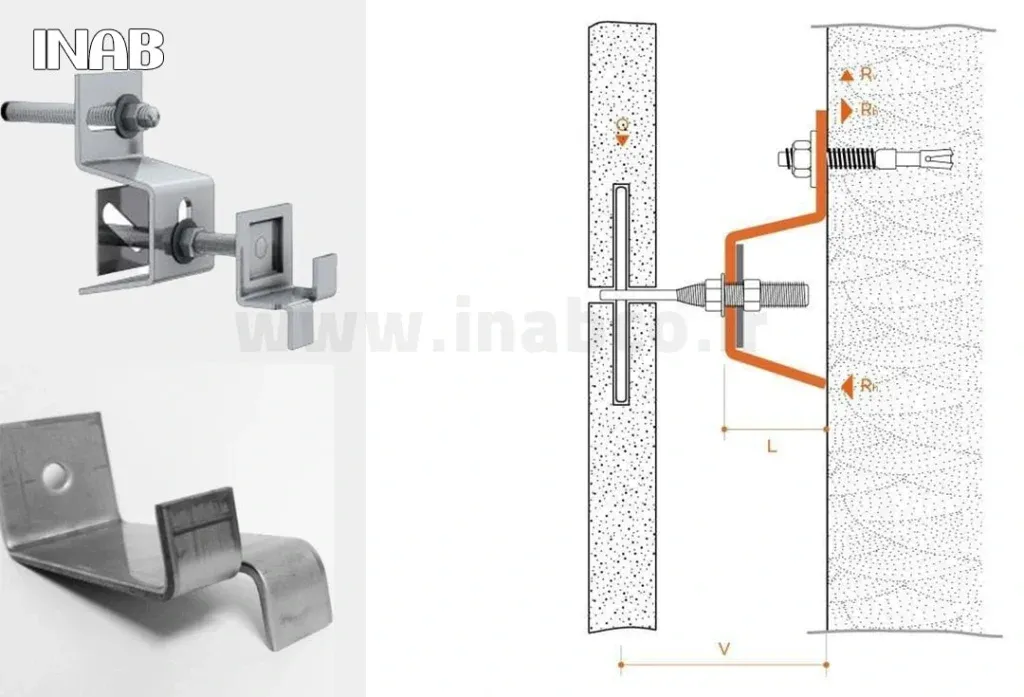

- Brackets and Anchors: Specialized fastening elements are employed to securely attach the profiles to the wall and to mount the panels onto the framework.

- GFRC Panel Installation: Panels are meticulously fixed to the integrated vertical and horizontal profiles using dedicated clips and brackets.

- Inspection and Finishing: A final series of inspections is conducted to verify correct installation, followed by any necessary adjustments and aesthetic refinements.

Advantages of Metal Framework Installation

- Design Flexibility: This methodology inherently accommodates the realization of complex and diverse architectural designs.

- Expedited Installation: The modular and often prefabricated nature of the components facilitates a fast and highly efficient installation process.

- Enhanced Durability: The utilization of corrosion- and rust-resistant metals significantly augments the long-term integrity and lifespan of the entire system.

2. Clip Systems

This methodology involves securing GFRC panels to the underlying structure or support system using specialized clips. These clips are engineered for concealment, thereby achieving a seamless façade aesthetic devoid of visible fasteners.

Components and Installation Steps

- Special Clips: Specifically designed clips that affix to the GFRC panels and securely interlock with the support profiles.

- Support Profiles: Structural profiles anchored to the building, serving as the interface for clip engagement.

- GFRC Panel Installation: Panels are connected to the support profiles via the integrated clip mechanisms.

- Inspection and Finishing: Comprehensive review to confirm accurate installation and execution of final adjustments.

Advantages of the Clip System

- Elegant and Seamless Appearance: Concealed connections yield a clean, uniform, and aesthetically refined façade surface.

- Enhanced Weather Resistance: Clips and profiles are fabricated from materials inherently resistant to corrosion, ensuring long-term performance.

- Simplified Maintenance: Panels are readily accessible for facile replacement or repair as required, minimizing disruption.

3. Rail Systems

In this approach, GFRC panels are precisely mounted onto horizontal or vertical rails. These rails are securely affixed to the building wall, allowing panels to be seamlessly slid into their designated positions.

Components and Installation Steps

- Horizontal or Vertical Rails: Rails are rigidly secured to the building structure, providing the linear framework into which panels are inserted.

- Support Profiles: Auxiliary profiles that ensure the secure and stable attachment of the rails to the wall.

- GFRC Panel Installation: Panels are carefully guided and slid into position within the prepared rail framework.

- Inspection and Finishing: Final verification of correct installation and performance of necessary adjustments.

Advantages of Rail Installation Method

- Expedited Installation: The modular, sliding nature of this system facilitates rapid and efficient panel installation.

- Ease of Maintenance: Panels can be replaced or repaired with minimal effort, often without requiring the dismantling of the entire façade section.

- Design Versatility: This method supports the realization of diverse and innovative design patterns, offering significant architectural flexibility.

4. Precast Systems

This method involves the off-site manufacturing of GFRC panels in a controlled factory environment, followed by their transportation to the project site. These meticulously produced panels are then attached to the building structure using either mechanical or chemical fasteners.

Components and Installation Steps

- Precast Panels: GFRC panels that are fully manufactured and prepared for direct installation at the factory.

- Mechanical or Chemical Fasteners: Specialized connectors employed to securely bond the panels to the building’s primary structure.

- Panel Installation: The precast panels are systematically affixed to the structure utilizing the chosen fastening mechanisms.

- Inspection and Finishing: A final verification process to ensure accurate installation, followed by any requisite adjustments.

Advantages of Precast Systems

- Superior Quality: Factory-controlled production environments ensure consistent, high-quality, and precise panel fabrication.

- Expedited Installation: On-site installation is significantly faster, directly contributing to reduced overall construction timelines.

- Exceptional Durability: Precast panels inherently offer superior strength and demonstrate long-lasting performance characteristics.

Conclusion: GFRC Dry Façade Installation

The selection of the appropriate installation method for GFRC dry façades is contingent upon the specific requirements and prevailing conditions of each project. Each distinct installation system possesses its own unique advantages and disadvantages, necessitating careful evaluation. Metal framework systems, clip systems, rail systems, and precast systems all contribute to enhancing the efficiency, aesthetics, and long-term durability of the building façade. The judicious choice of the installation method plays a pivotal role in determining the final quality and sustained performance of the façade.

Advantages of GFRC Dry Façades

- Lightweight: A paramount advantage of GFRC compared to conventional concrete is its significantly lower weight, which effectively reduces the dead load on the building structure.

- High Strength: GFRC exhibits excellent tensile and flexural strength, making it eminently suitable for a diverse range of architectural applications.

- Design Flexibility: Owing to its remarkable formability, GFRC enables the execution of highly complex and diverse design patterns.

- Durability and Longevity: This material demonstrates robust resistance to various environmental conditions, including freezing, extreme heat, and moisture, thereby ensuring an extended service life.

- Effective Insulation: GFRC provides commendable thermal and acoustic insulation properties, contributing to enhanced energy efficiency within buildings.

- Simplified Installation: Being lightweight and conducive to production as prefabricated panels, GFRC facilitates quick and straightforward installation processes.

Applications of GFRC Dry Façades

- Exterior Building Facades: Given its attractive aesthetics and favorable technical properties, GFRC is extensively utilized for the exterior cladding of residential, commercial, and office structures.

- Decorative Elements: Its superior formability positions GFRC as an ideal material for crafting intricate architectural features, including columns, domes, and window surrounds.

- Precast Walls: GFRC’s combination of lightweight and high strength significantly enhances construction efficiency when employed in precast wall panel applications.

- Interior Facades: GFRC also serves as an interior decorative medium, well-suited for wall and ceiling cladding.

Conclusion: GFRC Dry Façade

GFRC dry façade, a composite material integrating concrete and glass fibers, represents an innovative and highly efficient solution within the construction industry. Boasting advantages such as lightweight composition, high strength, design flexibility, and exceptional durability, it has become a favored choice for contemporary façade applications. While initial costs and the requirement for specialized technical expertise during installation may pose considerations, its substantial long-term benefits—particularly in terms of reduced maintenance expenditures and enhanced energy efficiency—underscore its value proposition. Opting for GFRC in building facades empowers architects and builders to realize highly creative and efficient design solutions.

2. Dry Ceramic Façade: A Comprehensive Explanation

The dry ceramic façade stands as a modern façade typology that has gained widespread adoption in the construction industry in recent years, owing to its distinct features and high performance. This system is a variant of the dry façade where ceramic tiles are mechanically affixed to the underlying façade structure. A key characteristic of this system is the creation of a ventilated air gap between the ceramic tiles and the main wall, which facilitates natural air circulation and enhances thermal insulation. The notable advantages of dry ceramic facades encompass high durability, robust resistance to diverse weather conditions, and simplified maintenance and repair procedures.

Components of Dry Ceramic Façade

- Ceramic Panels: Fabricated from high-quality ceramic materials, these panels offer extensive flexibility in architectural expression due to their diverse designs and color palettes.

- Mechanical Fastening System: This comprehensive system comprises rails, clips, and specialized screws, ensuring the secure attachment of the ceramic panels to the building structure.

- Insulation Layer: Frequently, a thermal and acoustic insulation layer is incorporated between the ceramic panels and the building wall to significantly enhance the structure’s energy efficiency.

- Supporting Profiles: Typically constructed from aluminum or steel, these profiles provide the necessary structural support and stability for the ceramic panels.

Installation Systems for Dry Ceramic Façades

Two primary systems govern the installation of dry ceramic façades: Exposed Systems and Concealed Systems. Each system presents distinct characteristics, advantages, and disadvantages. A comprehensive overview of these two installation methodologies follows.

Exposed System

In the exposed system, the fasteners and brackets securing the ceramic panels to the underlying structure remain visible. These connections are directly positioned on the outer surface of the façade and are typically manufactured from corrosion-resistant metals.

Components of the Exposed System

- Ceramic Panels: These constitute the primary cladding material for the façade.

- Supporting Profiles: Metal profiles securely attached to the building’s main structure.

- Clips and Brackets: Metal fasteners that connect the ceramic panels to the profiles; these are intentionally designed to be visible as an integral part of the aesthetic.

- Protective Coatings: Certain fasteners may receive protective treatments to bolster their resistance against rust and corrosion.

Advantages of the Exposed System

- Easier Installation: The visibility of connections streamlines the installation process, leading to quicker completion times.

- Lower Cost: Exposed systems feature a simpler design, eliminating the need for hidden fasteners, which translates to reduced material and installation expenditures.

- Simplified Maintenance and Repair: Visible connections offer ready accessibility, making repairs or replacements more expedient and cost-effective

Disadvantages of the Exposed System

- Less Refined Appearance: Visible fasteners can detract from the façade’s overall aesthetic appeal and uniformity, potentially imparting a more utilitarian or industrial character.

- Reduced Weathering Resistance: Exposed connections may exhibit increased vulnerability to rust and corrosion, necessitating more frequent maintenance interventions.

Concealed System

In the concealed system, the fasteners and brackets used to attach the ceramic panels to the building structure are entirely hidden from view. This system is engineered to create a seamless façade appearance without any visible connections.

Components of the Concealed System

- Ceramic Panels: These panels function as the primary cladding material for the façade.

- Support Profiles: Metal profiles securely affixed to the building’s main structural frame.

- Hidden Clips and Fasteners: Specially engineered connectors that are entirely obscured behind the panels, remaining invisible from the façade’s exterior surface.

- Insulation Layers: In numerous applications, a thermal and acoustic insulation layer is strategically installed between the ceramic panels and the building wall.

Advantages of the Concealed System

- Superior Aesthetic and Uniformity: The absence of visible fasteners results in a truly seamless, highly attractive, and modern façade finish.

- Enhanced Weathering Resistance: Concealed fasteners are less susceptible to environmental exposure, thereby reducing the risk of corrosion and rust, which contributes to the façade’s overall durability.

- Improved Insulation Performance: Concealed systems frequently integrate more robust thermal and acoustic insulation, consequently boosting the building’s energy efficiency.

Disadvantages of the Concealed System

- Higher Cost: Due to the inherent design complexity and the specialized hidden fasteners required, concealed systems typically entail greater material and installation expenses.

- Increased Installation Complexity: Installation demands a higher degree of precision and specialized expertise, which can potentially extend project timelines and increase labor costs.

- More Challenging Maintenance: Accessing hidden fasteners for repair or replacement purposes can be a time-consuming and costly undertaking.

Installation Steps for Exposed and Concealed Systems

Exposed System

- Surface Preparation: Thorough cleaning and preparation of the wall surface in readiness for profile installation.

- Installing Support Profiles: Affixing the structural profiles directly to the building wall.

- Installing Ceramic Panels: Securing the ceramic panels to the profiles using visible clips and fasteners.

- Inspection and Final Adjustments: Verifying the correctness of the installation and executing any necessary concluding refinements.

Concealed System

- Surface Preparation: Comprehensive cleaning and preparation of the wall surface for profile installation.

- Installing Support Profiles: Attaching the structural profiles to the building wall.

- Installing Insulation Layers: Placement of thermal and acoustic insulation layers, if required by the project specifications.

- Installing Ceramic Panels: Fixing the ceramic panels to the profiles using the designed hidden clips and fasteners.

- Inspection and Final Adjustments: Confirming the accuracy of the installation and implementing any requisite final adjustments.

Conclusion: Exposed vs. Concealed Ceramic Systems

The determination between an exposed and a concealed system for dry ceramic cladding is predicated upon the specific priorities and requirements of the project. The exposed system, characterized by its simpler installation and lower cost, is generally more appropriate for projects operating under budgetary constraints. Conversely, the concealed system, which delivers superior aesthetics and enhanced resistance to environmental elements, represents a more favorable option for projects where visual appeal and long-term durability are paramount. The judicious selection of the installation system significantly influences the ultimate performance, aesthetic quality, and longevity of the building façade.

Advantages of Dry Ceramic Facade

- Aesthetic Appeal and Design Variety: Ceramic panels come in a wide range of colors, patterns, and textures, enabling creative and attractive architectural designs.

- Durability and Longevity: Due to their high resistance to various weather conditions, sunlight, freezing, and temperature changes, ceramic facades have a long service life.

- Fire Resistance: Ceramics are fireproof and withstand high temperatures, enhancing building safety.

- Thermal and Acoustic Insulation: Incorporating insulating layers in dry ceramic facade systems improves thermal and sound insulation of the building.

- Fast and Easy Installation: Mechanical fixing systems allow for quick and precise installation of dry ceramic facades.

- Low Maintenance: Ceramic panels are easy to clean and require minimal maintenance.

Applications of Dry Ceramic Facades

- Commercial and Office Buildings: Their aesthetic and durability make them ideal for commercial and office complexes.

- Residential Buildings: Thermal and acoustic insulation improve residents’ comfort.

- Renovation Projects: Quick and easy installation makes dry ceramic facades suitable for refurbishing older buildings.

- Public Spaces: Due to high resistance and ease of maintenance, they are widely used in shopping centers, hotels, and hospitals.

Summary: Dry Ceramic Façades

Dry ceramic façades integrate beauty, durability, and high performance, positioning them as a popular and effective choice for building envelopes. Despite initial investment costs and the requirement for specialized technical expertise, their long-term benefits robustly justify their adoption. This system effectively empowers architects and builders to deliver creative, safe, and highly efficient designs.

3. Aluminum Composite Dry Façade: A Comprehensive Overview

Aluminum composite facade panels constitute a modern, lightweight cladding system, fundamentally composed of two aluminum layers sandwiching a core (typically polyethylene, mineral, or wood-based composites). Their surface coating, commonly PVDF or polyester, provides exceptional resistance to weathering, UV radiation, and environmental pollution. These panels inherently possess high impact resistance, windproof capabilities, effective thermal and acoustic insulation properties, and are fully recyclable. Furthermore, their expansive range of available colors, textures, and designs facilitates the creation of highly aesthetic and distinctly unique façades.

Components of Aluminum Composite Dry Facade System:

Aluminum Composite Panels:

Consisting of two aluminum layers bonded to a core, which may be plastic or mineral-based.

- Supporting Profiles:

Metal profiles that are attached to the building’s structural framework to support the composite panels. - Mechanical Fasteners:

Includes screws, clips, and specialized brackets used to secure the panels to the supporting profiles. - Thermal and Acoustic Insulation:

In some cases, insulation layers are installed between the composite panels and the building wall to enhance energy efficiency and soundproofing.

Advantages of Aluminum Composite Dry Facade System:

- Aesthetic Appeal & Design Flexibility:

Available in a wide range of colors and patterns, allowing for creative and versatile architectural designs. - Durability & Longevity:

Aluminum is highly resistant to corrosion and rust, ensuring long-lasting performance. - Lightweight:

Lighter than many traditional materials, reducing the structural load on the building. - Quick & Easy Installation:

Mechanical fastening systems enable rapid and straightforward installation. - Thermal & Acoustic Insulation:

Adding insulation layers within the system improves thermal and acoustic performance. - Fire Resistance:

Panels with mineral cores provide excellent fire resistance, enhancing building safety. - Low Maintenance:

Composite panels are easy to clean and require minimal maintenance.

Installation Methods for Aluminum Composite Dry Facade System:

Fixed System (Screw-Fixed Method):

This method is similar to the rail (hanging) system but instead of aluminum rails, metal box sections are used. The panels are fixed onto the metal sections using screws, rather than sliding into rails.

Key benefits of this method include lower overall costs compared to the rail system while retaining most of its advantages. It is the most popular installation method and is widely used in large, medium, and small projects, often approved by facade consultants and inspectors.

Installation Steps:

- Construct the metal substructure according to the facade design using metal box sections and angle brackets.

- Cut the composite sheets (standard size 320×125 cm) to the required dimensions.

- Assemble the cut panels into box shapes.

- Attach aluminum brackets and angles to the panels.

- Fix the panels onto the substructure using screws.

Advantages of Fixed System:

High-speed installation

- More cost-effective than the rail system

- Suitable for various shapes and volumetric designs

- Easy access to the substructure for future maintenance

- Allows for individual panel replacement

- Simultaneous thermal expansion of the panels and substructure prevents facade deformation.

Hanging (Rail) System:

In this method, aluminum profiles are used for the substructure. The composite panels are mounted onto the aluminum substructure by sliding them into rails.

This is considered the best method for installing composite facades due to its speed and precision, although it has a higher cost due to the use of aluminum and specialized fittings. It is generally recommended for large-scale and high-rise projects with uniform panel layouts, but not for small to mid-sized projects with irregular shapes.

Installation Steps:

- Build the metal substructure using box sections.

- Install metal brackets at designated locations.

- Install aluminum angle brackets at pre-defined points.

- Install the rail channels in position.

- Insert bolts into the rail channels.

- Sequentially: Cut, groove, and punch the composite panels.

- Bend and assemble the panels.

- Slide the panels into the rails for installation.

Advantages of Hanging (Rail) System:

- Simultaneous thermal expansion of panels and substructure prevents deformation.

- No need for sealing with rubber gaskets.

- High wind and seismic resistance.

- Each panel can be individually removed or replaced.

- Neat and organized aluminum connections.

- Easy access to the substructure for repairs.

- Precise panel alignment and adjustment.

Ziwar (H & L) System:

This non-standard method, primarily used in Iran, involves using L-shaped aluminum profiles on the edges of the panels for fixing side panels, and H-shaped profiles between adjoining panels.

Here, the substructure is built similarly to the fixed method, using metal box sections. The composite panels are then installed onto the substructure using aluminum Ziwar profiles, without overlapping panels. This reduces panel waste by approximately 10% to 20% since no overlaps are required.

Advantages of Ziwar (H & L) System:

- Fast installation

- Capable of accommodating custom shapes and curves

- Clean and uniform panel layout

- Usually requires no adhesives for waterproofing, although sealants may be used in some projects for additional sealing.

4. Precast Exposed Concrete Dry Façade

Precast exposed concrete panels are factory-manufactured façade elements characterized by their natural concrete finish. They deliver a modern, industrial aesthetic coupled with inherent high quality and exceptional durability.

Features of Precast Exposed Concrete Facades

- High Quality: These facades are produced using high-quality concrete and advanced technologies, allowing for the creation of concrete surfaces with a unique appearance.

- Easy Installation: Due to being precast, exposed concrete facades are ready for installation and are quickly transported to the site, which reduces installation time and cost.

- Durability: Because they use high-strength concrete, these facades are highly resistant to atmospheric factors and environmental conditions, ensuring a long lifespan and high durability.

- Design Variety: By incorporating different materials such as stone aggregates, cement powder, and other components, a wide variety of designs and appearances can be achieved in precast exposed concrete facades.

- Multiple Applications: These facades are widely used in residential, commercial, and industrial buildings and are considered a modern and durable choice for exterior design.

Overall, precast exposed concrete facades are an excellent option for designers and architects seeking to use high-quality concrete with a natural and industrial look in buildings, as well as a fast and cost-effective facade installation solution.

Advantages of Exposed Concrete Facades

- Beautiful and Unique Appearance: Precast exposed concrete gives a building a beautiful and distinctive look. The high-quality exposed concrete surface, along with various aggregates or decorative materials, adds aesthetic design to the facade.

- Resistance and Durability: The high-quality concrete used in precast exposed concrete facades offers high resistance to weather elements, abrasion, impact, and more. These features make precast exposed facades suitable for various environments, including commercial and industrial buildings, and ensure high durability.

- Fast Installation and Reduced Costs: Precast exposed concrete facades significantly reduce installation time due to being factory-prepared and quickly installed on-site. This leads to lower installation costs and reduces the need for extensive labor and complex equipment.

- Design Versatility: Precast exposed concrete facades offer high versatility in design and the use of various materials in their construction, allowing for diverse patterns and designs. This enables designers to implement more creative architectural schemes.

- Reduced Energy Consumption: Precast exposed concrete, due to its thermal properties and low light reflectivity, can help reduce building energy consumption as it requires fewer additional coatings or heat transfer systems.

- Environmental Friendliness: Using precast exposed concrete as an eco-friendly building material can lead to reduced construction waste generation and more efficient use of natural resources like natural stone.

In general, precast exposed concrete facades, combining the natural beauty of concrete with technical and economic advantages, are a suitable option for modern and sustainable buildings seeking attractive and durable facades.

Installation of Exposed Concrete Facades with the Dry System

The dry installation system is the best method for building facade installation. Generally, this method consists of two main parts: substructure and facade cladding. The facade substructure is created using metal boxes, angles, and other metal profiles, according to as-built drawings and facade requirements. After that, the facade cladding panels are installed onto the substructure.

A key feature of the dry facade system is that the connection of the facade cladding to the substructure can be achieved in various ways for different facades, allowing for a wide range of design and implementation methods.

How to Install Dry Exposed Concrete Using Inab’s Proprietary Method

Inab’s proprietary installation method is designed to be effective in installing various facades, including exposed concrete. This method is a fixed installation, executed with galvanized metal clips and screws. It is fast, easy, highly safe, does not require access to the back of the facade, and is very practical for repair and modification.

In this method, the facade substructure is first created in a grid pattern using metal boxes, based on the dimensions of the tiles. Then, the exposed concrete tiles are placed onto the substructure and attached to it using galvanized self-drilling screws.

Exposed Concrete Installation with Through-Screwing Method

In some types of exposed concrete molds, indentations are created in the concrete. These indentations in the panels, in addition to their unique aesthetic, also serve as attachment points for the tiles. From these bolt locations, the exposed concrete panels can be drilled, and the tiles can be attached to the facade substructure. The facade substructure in this method must be designed so that the substructure boxes are positioned at these drilled holes to allow the panels to be attached to the substructure with screws.

Exposed Concrete Installation with Screw Anchor and Adhesive Method

This installation method is used for exposed concrete facades in interior decoration. Exposed concrete tiles used in interior facade design, due to their lower height and relatively lighter weight compared to building facades, do not require strong and robust structures for their substructure. Furthermore, a substructure requires space, and some space must be allocated for it, which is not cost-effective for interior spaces. Therefore, in interior spaces, the adhesive and screw anchor method is typically used. Special adhesives are usually sufficient for the weight of concrete tiles, but to ensure greater safety of the tiles after installation, screw anchors are also used. Screw anchors are installed directly on the wall and do not require a substructure.

Exposed Concrete Installation with Welding Method

In the welding method for exposed concrete installation, metal pieces are placed at various points on the back or along the width of the exposed concrete panels. Using these metal pieces, the tiles are welded to the facade substructure. The welding method is generally less common than screw installation because repairing and modifying the facade would be much more difficult and costly compared to the screw method.

5. Dry Stone Façade: A Comprehensive Explanation

A dry stone façade represents a modern and efficient cladding methodology wherein natural or engineered stones are mechanically affixed to the building structure without the use of mortar.

Components

- Natural or Artificial Stones: Examples include granite, marble, or travertine, selected for their aesthetic and physical properties.

- Support Profiles: Aluminum or steel profiles that provide the structural framework for holding the stone panels.

- Mechanical Fasteners: A variety of securing elements such as screws, clips, hooks, and brackets, used to firmly attach stones to the support profiles.

- Thermal and Acoustic Insulation: Optional insulating layers that can be integrated to enhance the building’s overall energy performance.

- Sealants and Water Barriers: Applied to prevent moisture infiltration and ensure weather-tightness.

Advantages of Dry Stone Façade

- Exceptional Durability and Longevity: Natural stones inherently exhibit high resistance to diverse weather conditions and physical wear, ensuring a prolonged service life.

- Superior Aesthetic Appeal and Luxury: Owing to their unique natural patterns and varied colors, natural stones impart an unparalleled and luxurious beauty to building façades.

- Rapid and Efficient Installation: The utilization of mechanical fasteners significantly reduces installation time and associated labor costs.

- Ease of Replaceability and Repair: Damaged sections can be readily replaced without necessitating the dismantling of the entire façade system.

- Enhanced Thermal and Acoustic Insulation: The integration of insulation layers effectively contributes to improved building energy efficiency.

- Inherent Fire Resistance: Natural stones are typically non-combustible, adding a significant layer of fire safety to the structure.

- Minimal Maintenance Requirements: Natural stone façades generally demand less ongoing maintenance compared to many other façade materials.

Disadvantages of Dry Stone Façade

- High Initial Cost: The procurement and installation of natural stones, coupled with the required mechanical fasteners, can entail greater expense compared to other façade materials.

- Significant Weight: Natural stones are inherently heavy, necessitating more robust supporting structures and potentially influencing overall building design.

- Technical Expertise Required: The installation of a dry stone façade demands specialized technical knowledge and skilled craftsmanship.

Installation Methods of Dry Stone Façade

1. Clip System

In this method, stones are securely attached to support profiles using metal clips. These clips are specifically designed to ensure that the fastenings remain entirely invisible.

Components and Installation Steps

- Support Profiles: These profiles are rigidly fixed to the building’s main wall.

- Clips: Clips are meticulously attached to the individual stone pieces and subsequently locked onto the support profiles.

- Stone Installation: Stones are firmly secured to the profiles via the clip mechanisms.

- Inspection and Finishing: A final verification process to confirm accurate installation and perform any necessary concluding adjustments.

Advantages of Clip System for Dry Stone Façade

- Seamless Aesthetic: Achieves a uniform appearance with no visible fasteners, enhancing visual continuity.

- High Weather Resistance: Provides robust performance against various weather conditions due to protected fastenings.

- Rapid and Efficient Installation: Contributes to a quicker and more streamlined installation process.

Disadvantages of Clip System for Dry Stone Façade

- Higher Cost: Typically involves greater material and labor costs compared to some alternative methods.

- Precision Requirement: Demands a very high degree of precision during installation to ensure proper alignment and secure fastening.

2. Hook System

In this method, stones are attached to the support profiles using metal hooks. These hooks are securely fixed to the reverse side of the stones and then precisely interlocked onto the profiles.

Components and Installation Steps:

- Support Profiles: These structural profiles are rigidly secured to the building’s main wall.

- Hooks: Specialized hooks are meticulously attached to the back surface of the individual stone units.

- Stone Installation: Stones are precisely engaged and locked onto the support profiles via the hook mechanisms.

- Inspection and Finishing: A final verification is conducted to confirm accurate installation, followed by any necessary concluding adjustments.

Advantages of the Hook System:

- Rapid and Efficient Installation: Facilitates a swift and streamlined installation process.

- Simplified Replacement and Repair: Allows for relatively easy removal and re-installation of individual stone units for maintenance or repair.

- Enhanced Durability: Contributes to the overall long-term stability and resilience of the façade.

Disadvantages of the Hook System:

- Higher Initial Cost: May involve greater material and labor expenses compared to some alternative methods.

- Precision Requirement: Demands a high degree of accuracy during the installation phase to ensure optimal alignment and secure attachment.

3. Bolt and Nut System

In this method, stones are attached to the support profiles using bolts and nuts. Holes are precisely drilled into the stone units, through which bolts are passed to secure them to the profiles.

Components and Installation Steps

- Support Profiles: These profiles are rigidly attached to the building’s main wall.

- Bolts and Nuts: Bolts are inserted through pre-drilled holes in the stone panels and then fastened with nuts to connect them securely to the support profiles.

- Stone Installation: Stone panels are robustly secured to the profiles using the bolt and nut assemblies.

- Inspection and Finishing: A final verification is conducted to confirm accurate installation and to perform any necessary concluding adjustments.

Advantages of the Bolt and Nut System

- Robust and Stable Installation: Provides a highly secure and stable attachment for the stone panels.

- Exceptional Durability: Contributes to the long-term resilience and structural integrity of the façade.

- Facilitated Replacement and Repair: Individual stone panels can be relatively easily replaced or repaired, if necessary, by accessing the bolted connections.

Disadvantages of the Bolt and Nut System

- Reduced Aesthetic Appeal: The visible connections can detract from the seamless visual continuity of the façade, potentially lending a more utilitarian appearance.

- Precision Requirement: Demands a high degree of precision during the drilling and installation phases to ensure proper alignment and secure fastening.

4. Rail System

In this method, stones are precisely positioned on horizontal or vertical rails, which are securely attached to the building’s main wall. The stones are then slid into these rails for installation.

Components and Installation Steps

- Horizontal or Vertical Rails: These structural rails are rigidly fixed to the building’s wall.

- Stones: Individual stone units are guided and slid into their designated positions within the rail framework.

- Inspection and Finishing: A final verification is conducted to confirm accurate installation and to perform any necessary concluding adjustments.

Advantages of the Rail System

- Rapid and Efficient Installation: Facilitates a swift and streamlined installation process.

- Simplified Maintenance and Repair: Allows for relatively easy removal and re-insertion of individual stone units for maintenance or repair.

- Design Flexibility: Offers considerable adaptability for various design configurations.

Disadvantages of the Rail System

- Higher Initial Cost: May involve greater material and labor expenses compared to some alternative methods.

- Design Constraints: Can present limitations when attempting to implement highly complex or curvilinear designs.

Conclusion: Dry Stone Façade

Given its numerous advantages, dry stone cladding has emerged as a popular and highly efficient choice in contemporary building façade design and execution. This system, boasting benefits such as exceptional durability, inherent aesthetic appeal and luxury, rapid and straightforward installation, ease of repair, superior thermal and acoustic insulation, and intrinsic fire resistance, has firmly established itself as a modern and well-regarded methodology within the construction industry. The selection of the appropriate installation method for dry stone cladding is contingent upon the specific needs and prevailing conditions of the project, profoundly impacting the final quality and long-term performance of the façade. Each distinct installation method—including the clip system, hook system, bolt and nut system, and rail system—possesses its own unique advantages and disadvantages that necessitate meticulous evaluation.

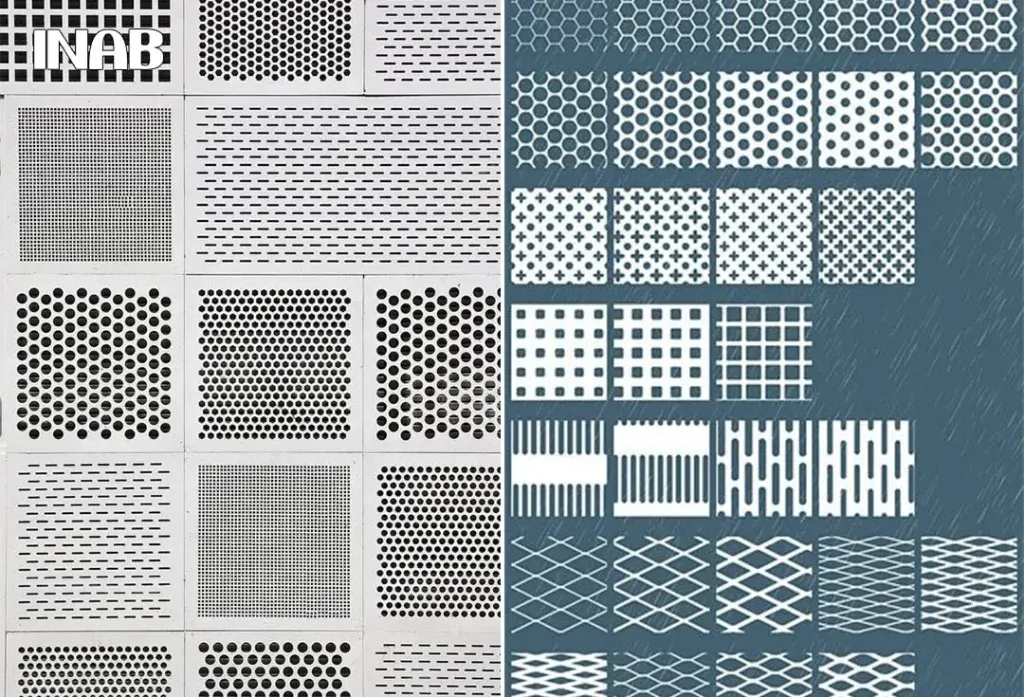

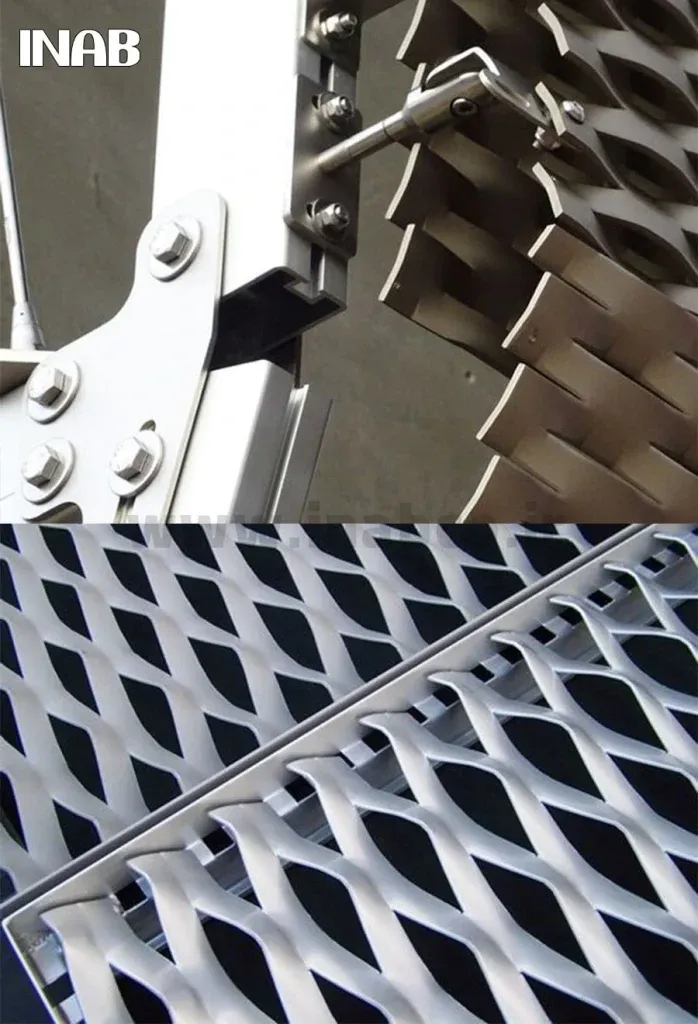

6. Stretch Metal Dry Façade

Imagine a building clad in gleaming metal, artistically reflecting sunlight and adorned with intricate geometric patterns. This evocative effect is precisely what stretch metal or perforated metal façades bring to modern architecture. Combining aesthetic appeal, structural integrity, and multifaceted functionality, these striking façades have emerged as a highly favored choice among architects and designers. This article delves into the features, advantages, disadvantages, installation methods, and diverse applications of stretch metal and perforated metal façades.

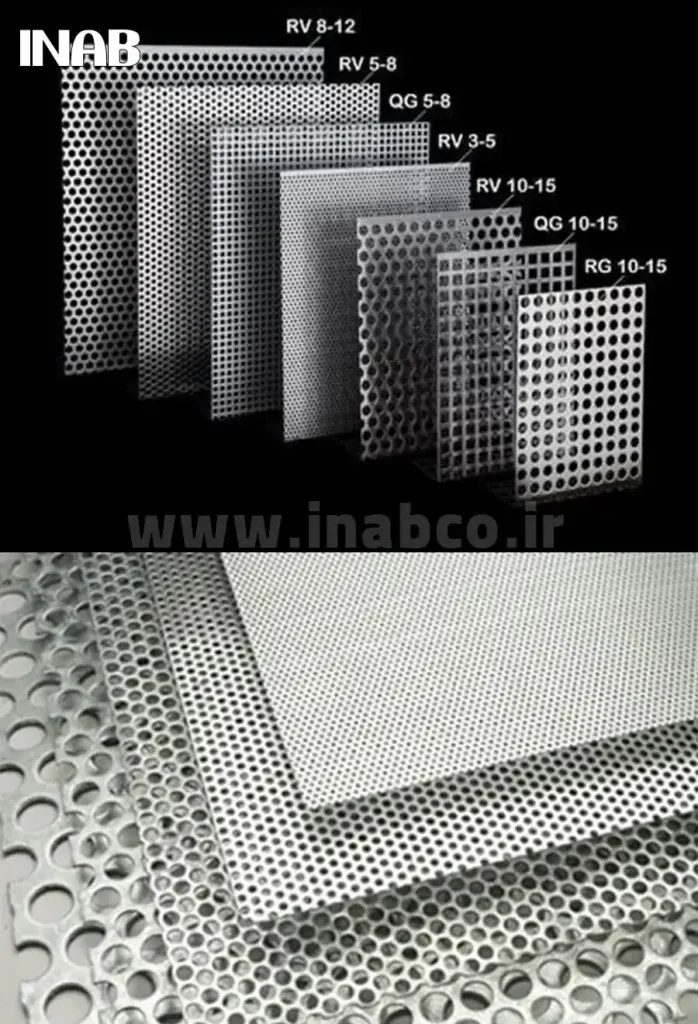

Features and Differences Between Stretch Metal and Perforated Metal

- Stretch Metal: Refers to metal sheets that have been simultaneously stretched and slit in a regular pattern, forming a mesh-like, cohesive structure. This type of façade typically presents an organic, three-dimensional appearance.

- Perforated Metal: Consists of metal sheets into which various geometric holes are precisely punched, creating diverse and orderly patterns. This façade variant generally exhibits a more geometric and uniform visual quality.

Advantages of Using Stretch Metal and Perforated Metal Façades

- Unique Aesthetic and Design: The extensive variety of available patterns and designs enables the creation of distinctly modern and visually captivating façades.

- Durability and High Resistance: The inherent metallic composition provides robust resistance against diverse weather conditions and environmental factors.

- Lightweight: Imposes a reduced dead load on the building structure, making it particularly suitable for high-rise constructions.

- Effective Ventilation: The inherent perforations facilitate natural airflow, effectively preventing excessive heat buildup within the building envelope.

- Fire Resistance: The metals commonly employed in these façades offer excellent intrinsic fire resistance.

- Design Flexibility: These materials can be seamlessly integrated and combined with other diverse building materials, such as glass and wood, for enhanced architectural expression.

Disadvantages and Challenges of Installing These Façades

- Elevated Cost: Compared to certain other façade typologies, these systems generally entail higher installation expenditures.

- Maintenance Requirement: Regular cleaning and routine upkeep are essential to preserve their intended aesthetic appeal.

- Susceptibility to Corrosion: Absent adequate protective coatings, the metallic sheets can be prone to corrosive degradation.

- Precision Installation Mandate: The installation process necessitates a high degree of accuracy and specialized technical expertise.

Installation Methods for Stretch Metal and Perforated Metal Façades

- Direct Mounting on the Façade: The metal sheets are affixed directly onto the building’s primary substrate.

- Installation Using Metal Frames: The sheets are mounted onto a dedicated metal framework, which is subsequently attached to the building structure.

- Dry Installation: The sheets are installed without the use of mortar, employing specialized dry connection systems.

Applications of Stretch Metal and Perforated Metal Façades

- Commercial Buildings: Utilized to craft modern and visually engaging façades for office buildings, shopping centers, and hotels.

- Residential Buildings: Employed for designing distinctive and aesthetically pleasing exteriors for apartments and villas.

- Industrial Buildings: Provides both protective and aesthetic cladding solutions for warehouses and factories.

- Other Uses: Extends to the construction of canopies, railings, false ceilings, and similar architectural elements.

Important Considerations in Design and Implementation

- Material Selection: The appropriate metal type should be chosen based on prevailing climatic conditions and the specific building typology.

- Protective Coating: The application of suitable coatings, such as powder coating or anodizing, is crucial to enhance the façade’s lifespan and resistance.

- Professional Installation: Entrusting the installation process to experienced teams is paramount for achieving optimal results and ensuring system integrity.

Summary: Stretch Metal and Perforated Metal Façades

Stretch metal and perforated metal façades represent exceptional choices for creating modern, aesthetically appealing, and durable building exteriors. Due to their numerous advantages and inherent design versatility, these façades have secured a prominent position within contemporary architecture. With the judicious selection of material, meticulous design, and proficient execution, truly impressive and long-lasting results can be achieved.

Components of a Dry Facade System: Engineered for Performance and Aesthetics

A dry facade system is a high-performance, mortar-free cladding solution that uses mechanical fasteners to provide superior durability, thermal efficiency, and design flexibility. Engineered as a multi-layered assembly, it meets the complex requirements of contemporary architecture—balancing structural performance with visual refinement. Below is an overview of the core components of a dry facade system, detailing their functions, benefits, and relevance to diverse climates, including Iran’s hot and arid regions.

1. Metal or Aluminum Substructure

Description:

A network of brackets, vertical and horizontal rails, and support profiles anchored to the building’s structural wall.

Features:

Manufactured from corrosion-resistant galvanized steel or aluminum; includes adjustable elements to accommodate on-site tolerances and alignments.

Role:

Provides the structural backbone for the facade, transferring loads safely to the building’s main frame.

Benefit:

Enables flexibility for various design geometries and ensures long-term stability and safety.

2. Thermal and Acoustic Insulation Layer

Description:

Installed behind the outer cladding, this layer includes materials such as rock wool, glass wool, extruded polystyrene (XPS), or polyisocyanurate (PIR).

Role:

Reduces thermal bridging and external sound transmission, improving energy efficiency and indoor comfort.

Benefit:

Lowers heating and cooling demands, reduces operational costs, and improves occupant well-being.

3. Ventilated Air Gap

Description:

A continuous cavity between the insulation layer and the external cladding, allowing for passive airflow.

Role:

Prevents moisture buildup, promotes drying, and reduces the risk of mold or material deterioration.

Benefit:

Enhances thermal regulation, prolongs the facade’s service life, and supports healthy indoor environments.

4. Outer Cladding (Aesthetic Skin)

Description:

The visual and protective layer, available in a wide range of materials, including:

- GFRC (Glass Fiber Reinforced Concrete)

- Porcelain ceramic

- Travertine or natural stone

- Thermowood

- Fiber cement

- HPL (High-Pressure Laminate)

- Aluminum composite panels

- Frameless or laminated glass

Role:

Delivers architectural character while shielding the building from wind, UV radiation, rain, and pollutants.

Benefit:

Enables designers to achieve diverse aesthetics while meeting functional and climatic requirements.

5. Mechanical Fasteners

Description:

A system of stainless steel clips, brackets, rails, and screws used to mechanically attach cladding panels—without adhesives or mortar.

Role:

Securely holds facade components in place, allowing for movement, alignment, and maintenance access.

Benefit:

Accelerates installation, facilitates panel replacement, and minimizes site disruptions.

6. Expansion Joints and Waterproofing

Description:

Flexible seals and profiles made from silicone, EPDM rubber, or aluminum that accommodate thermal expansion and prevent water ingress.

Role:

Protects the building envelope from cracking, leakage, and weather-related deterioration.

Benefit:

Ensures facade performance and integrity across temperature fluctuations and varying humidity levels.

7. Sustainability and Installation Efficiency

Description:

Utilizes recyclable or low-impact materials, with modular components designed for precise, waste-minimized installation.

Role:

Supports sustainable design strategies and reduces environmental impact during construction and throughout the building’s lifecycle.

Benefit:

Contributes to LEED, WELL, and other green certifications, while ensuring performance in demanding climates like those found in Iran.

Conclusion

A dry facade system represents a strategic convergence of aesthetics, performance, and sustainability. Each component—when thoughtfully selected and professionally installed—plays a critical role in ensuring long-term success. Whether incorporating GFRC for its lightweight versatility or using high-efficiency insulation for thermal control, dry facade systems offer:

- Faster construction timelines

- Lower maintenance requirements

- Enhanced architectural expression

- Superior energy and moisture management

In regions such as Iran, adopting dry facade systems not only meets international standards but also paves the way for innovative, climate-resilient architecture that is as enduring as it is visually compelling.

Aluminum Louver Façade: A Blend of Aesthetics and Functionality

The aluminum louver façade stands as one of the most prominent and practical façade typologies in modern architecture. Its numerous advantages and inherent design versatility have secured it a distinct position within the construction industry. This system fundamentally comprises a series of aluminum slats installed either horizontally or vertically on the façade. These slats can be precisely angled to modulate natural light and ventilation, while concurrently serving as a protective layer against direct solar radiation.

Applications of Aluminum Louver Façades

- Commercial and Office Buildings: Employed to create contemporary façades and to significantly enhance energy efficiency.

- Residential Buildings: Utilized to improve occupant comfort and to reduce energy consumption associated with heating and cooling.

- Public Spaces: Provides effective shading in open areas and offers precise management of light penetration and airflow.

- Industrial Facilities: Offers robust protection for industrial equipment against diverse environmental exposures.

Advantages of Aluminum Louver Façades

- Light and Ventilation Control: Adjustable slats enable precise regulation of incoming natural light and prevent undesirable solar heat gain.

- Energy Savings: Contributes to a reduced building heat load, consequently lowering energy consumption for cooling and heating systems.

- Extended Building Lifespan: Offers protection to the underlying façade from weathering effects, thereby increasing its overall durability.

- Aesthetic Versatility: Possesses the capacity to generate diverse designs that effectively complement a wide array of architectural styles.

- High Durability: Aluminum inherently exhibits exceptional resistance to corrosion, moisture, and temperature fluctuations.

- Effortless Installation: Its lightweight nature facilitates quick and straightforward installation procedures.

Types of Aluminum Louver Systems

- Fixed Louvers: Slats are installed at a predetermined, unadjustable angle.

- Operable Louvers: Slats are capable of manual or automatic adjustment, allowing for dynamic environmental control.

- Spindle Louvers: Slats are designed with a distinctive spindle form, imparting a unique visual effect.

- Perforated Louvers: Slats incorporate various perforation patterns, enabling filtered entry of light and air into the building interior.

Methods of Aluminum Louver Facade Installation

Choosing the appropriate installation method depends on factors like building type, climate, budget, and architectural design. Below is a detailed overview of common installation methods:

Framed System

Louvers are placed within a metal frame (usually aluminum or steel), which is then attached to the building structure.

Advantages:

- Increased structural strength against external forces such as wind and earthquakes.

- Easier installation and maintenance.

- Design flexibility with various sizes and shapes.

- Creates a uniform, cohesive facade appearance.

Disadvantages:

- Adds weight to the structure.

- Higher costs due to additional materials and labor.

- Potential design limitations for highly complex facades.

Frameless System

Louvers are directly mounted onto the building substrate without a frame.

Advantages:

- Minimalist, clean appearance.

- Reduced dead load on the building.

- Greater design flexibility for complex and curved shapes.

Disadvantages:

- Requires precise installation and alignment.

- Some louver types may not be suitable for frameless mounting.

- More vulnerable to external forces if improperly installed.

3.Hybrid System

This system combines both framed and frameless approaches, utilizing framed sections in areas requiring higher structural resistance and frameless sections elsewhere.

Advantages:

- High flexibility, leveraging the benefits of both methods.

- Optimized project costs.

- Enables diverse and appealing designs.

Disadvantages:

More complex execution, requiring detailed planning and skilled labor.

4.Modular System

Louvers are prefabricated as modules in a factory and then assembled on-site.

Advantages:

- Faster project completion.

- Enhanced quality control under factory conditions.

- Reduced on-site errors.

Disadvantages:

- Potentially high transportation costs.

- Limited on-site design adjustments due to prefabrication.

Choosing the right installation method for your aluminum louver facade depends on several key factors:

Factors Influencing Method Selection

- Project Size: For larger projects, modular or framed systems are generally more suitable as they allow for faster and easier installation.

- Louver Type: If you’re using operable louvers, a framed system is typically required to ensure proper functioning and support.

- Climate: In areas prone to strong winds or heavy rainfall, framed systems are recommended due to their enhanced structural strength.

- Budget: While frameless systems can often cost less initially, they demand more precision and expertise during installation.

- Architectural Design: Highly complex or stylistically specific designs may necessitate particular installation methods to achieve the desired aesthetic and performance.

Selecting the right installation method is crucial for optimal facade performance and longevity. It’s always a good idea to consult with a building engineer or facade specialist before finalizing your choice.

Dry Brick Facade: A Modern and Efficient Building Envelope

A dry brick facade is an advanced exterior cladding system where bricks are installed without mortar or adhesive. Instead, bricks are mechanically fixed together using specialized retention systems connected directly to the main building structure. Thanks to its numerous benefits and versatile applications, dry brick facades have become a popular choice in recent years.

Advantages of Dry Brick Facade

- Lightweight and Reduced Dead Load: Eliminating mortar significantly lowers the overall facade weight. This reduces the structural load on the building and improves its resistance to earthquakes.

- Fast Installation: The installation process is much quicker than traditional methods, saving both time and cost.

- Design Variety: This system allows for the creation of complex and diverse patterns using various bricks and installation techniques.

- Ventilation and Thermal Insulation: The gap between the bricks and the main wall facilitates airflow, which helps prevent moisture buildup and provides excellent thermal insulation.

- High Durability: With quality materials and proper installation, dry brick facades can last for many years without requiring major repairs.

- Resistance to Environmental Factors: They perform exceptionally well against rain, snow, temperature extremes, and other harsh weather conditions.

- Easy Repair and Replacement: Damaged sections can be easily replaced without disturbing adjacent bricks, simplifying maintenance.

Applications of Dry Brick Facade

- Higher Initial Cost: Due to the need for specialized equipment and materials, the initial cost of implementing this type of facade can be higher than traditional methods.

- Need for Skilled Labor: Proper installation requires technical knowledge and specialized skills, meaning you’ll need experienced professionals for the job.

- Dependence on Connection Quality: The durability of the facade heavily relies on the quality of the connections and materials used. Opting for low-quality materials will significantly reduce its lifespan.

- Requirement for Proper Insulation: To maximize the building’s energy efficiency, it’s essential to install appropriate thermal insulation behind the facade.

Applications of Dry Brick Facade

Dry brick facades are highly versatile and can be used in a wide range of buildings, including residential, commercial, administrative, industrial, and public structures. Their applications include:

- Villas and Apartments: Perfect for creating a beautiful and modern aesthetic.

- Commercial Centers and Hotels: Ideal for designing eye-catching and visually appealing facades that draw attention.

- Administrative and Public Buildings: Provides durable facades that are highly resistant to environmental conditions.

- Warehouses and Factories: Suitable for constructing robust and resilient industrial facades.

Brick Facade – Execution Details & Installation Methods

Dry facades are executed using various methods, each with its own advantages and disadvantages. The best method depends on factors like the material type, building height, facade design, and project budget. Here’s a detailed review of each common installation method:

1. Rail and Hook System

- Mechanism: In this method, metal rails are installed horizontally and vertically on the building’s main structure. Bricks or other facade materials are then hung on these rails using specialized hooks.

- Advantages: Offers high installation speed, allows for precise adjustment of bricks, and is suitable for complex and curved facades.

- Disadvantages: Requires a precise substructure and can be more costly compared to some other methods.

2. Screw and Rawlplug System

- Mechanism: With this method, bricks are directly attached to the wall or a metal substructure using screws and rawlplugs.

- Advantages: Suitable for heavy and thick bricks and provides high resistance to lateral forces.

- Disadvantages: Requires drilling into the bricks, and there’s a risk of cracks if screws are overtightened.

3. Hidden System

- Mechanism: In this method, the connections between bricks are concealed, achieved through the use of special metal components.

- Advantages: Creates a very clean and uniform appearance, and enables the creation of complex and geometric designs.

- Disadvantages: Involves a more complex installation process and generally comes with a higher cost.

4. Dry System with Spacers

- Mechanism: This method involves creating a gap between the bricks and the main wall, which facilitates air ventilation and prevents moisture accumulation. Spacers, typically made of plastic or metal, maintain this gap.

- Advantages: Leads to improved thermal and acoustic insulation and significantly increases the facade’s lifespan.

- Disadvantages: Requires high precision when installing the spacers.

Conclusion: Dry Façade Systems

In conclusion, the dry façade system has emerged as one of the most advanced and efficient methods for façade installation, securing a prominent position in the construction industry. In this article, we aimed to introduce the various materials used in this system, review their advantages and disadvantages, and provide insights into installation methods along with some relevant technical details.

With its flexibility in design, resistance to environmental factors, and ease of replacing or repairing individual components, the dry façade system has become an ideal solution for modern construction projects.

We hope this information assists you in making better decisions regarding the selection and installation of dry façade systems and contributes to creating more beautiful, durable, and sustainable projects.